Power output ranging from approximately 25 to 70 horsepower. This is the range covered by Yanmar engines designed to power high and medium-flow pump systems for irrigation or construction, systems that, in most cases, are required to operate for long periods under variable loads and speeds, as well as in full autonomy, without constant or direct supervision by an operator.

Dedicated Product Line

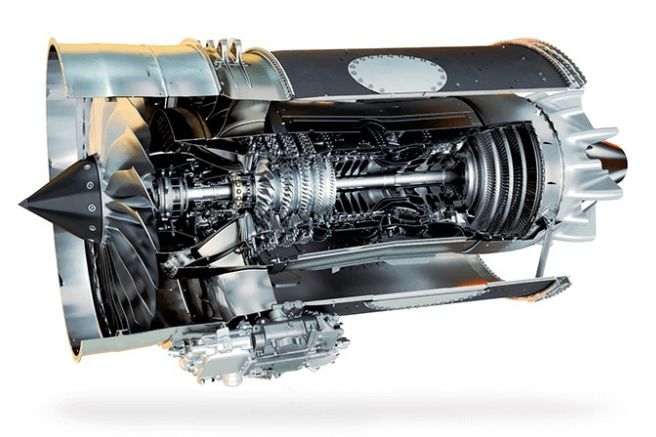

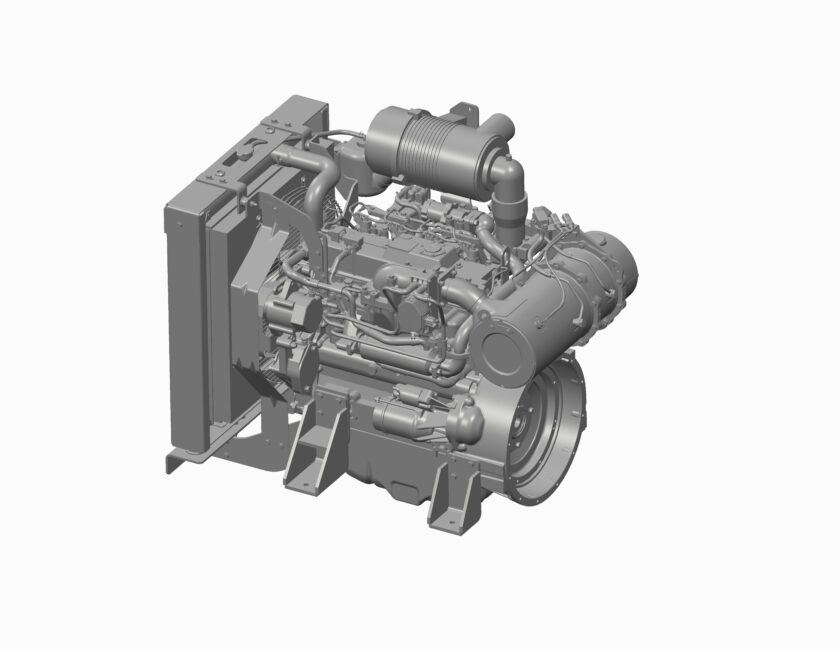

A demanding operational profile, for which Yanmar has developed a specific product line based on four different three- and four-cylinder units, all Stage V compliant and offered in a package with their respective auxiliary service systems: radiator, fan, alternator, starter motor, air filter, and more. The lineup includes three units with power outputs ranging from 38 to 70 horsepower: the “3Tnv88C-Dsa,” “4Tnv88C-Dsa,” and “4Tnv98C-Nsa,” equipped with a common rail fuel system and an EGR system for intake, combined with a particulate filter (DPF) managed by a three-stage regeneration system. In the first two stages, “Assist” and “Regen,” the engine can operate between 1,500 and 1,800 RPM without any issues. If needed, regeneration can become stationary, setting the engine to a fixed speed of 1,500 RPM for 30 minutes. This solution, combined with the previous two, allows Yanmar to guarantee maintenance-free operation of the DPF for at least 6,000 hours of work.

Also a Compact Three-Cylinder

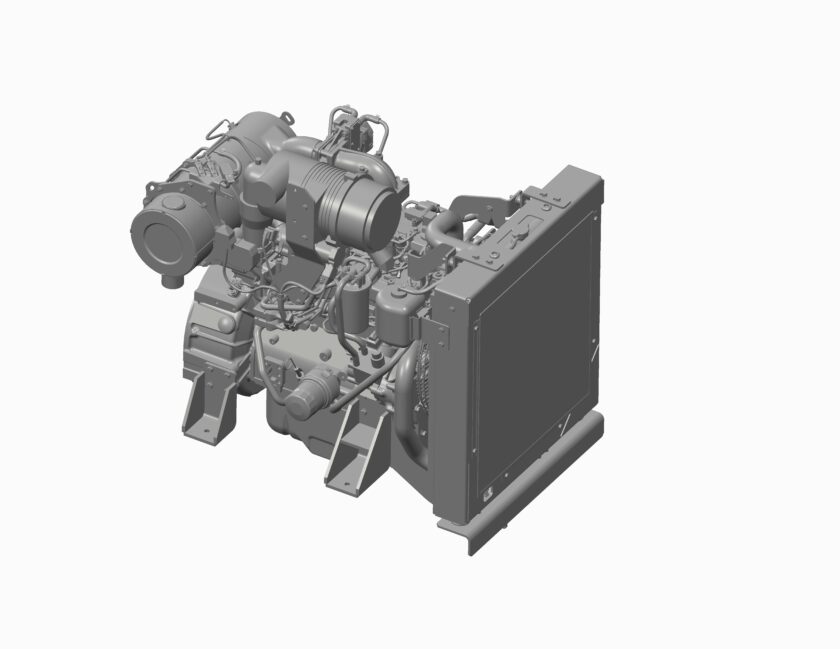

If the pump system does not require power exceeding 25 horsepower, Yanmar also offers a fourth engine unit based on a three-cylinder engine with 1,642 cubic centimeters, mechanically powered with electronic speed control. Labeled “3Tnv88F-Esgn,” this engine is also Stage V/Tier 4F compliant, operating at a maximum speed of 2,200 RPM and featuring an integrated exhaust muffler, which allows the pump system to work even in noise-sensitive environments.

Title: Yanmar range for motor pumps, also active 24 hours a day

Translation with ChatGPT