Ferrari has unveiled a potential future for its propulsion solutions by patenting an innovative inverted six-cylinder hydrogen-powered combustion engine, supported by an electrically driven supercharging system.

For now, it’s just a patent, one of many aimed at anticipating possible product developments in the short to medium term. The word “possible” is mandatory since many patents filed by the automotive sector never see the realization of their contents. However, they still generate interest and discussions, especially when referring to unconventional design solutions, as is the case with the patent filed by Ferrari in recent months regarding a new hydrogen-fueled combustion engine supported by an electrically driven turbocharger.

Beyond the limits of full electric

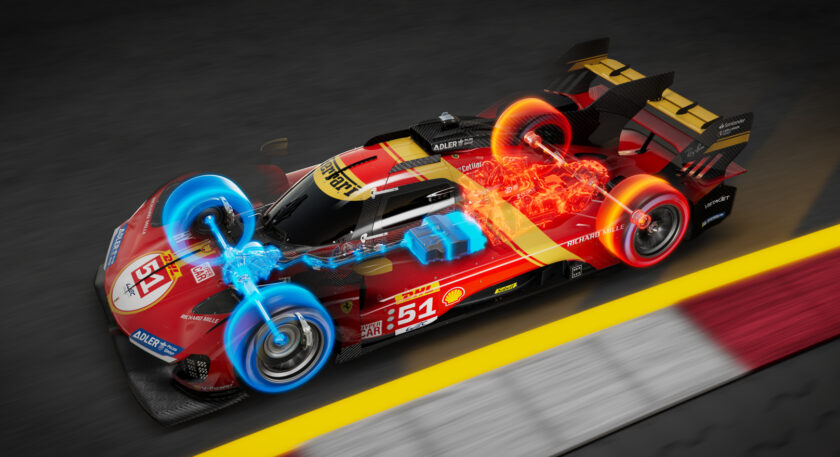

This solution confirms a concrete interest from Modena-based motor engineers in using hydrogen as a fuel within traditional endothermic engines, instead of the more common use as an energy source for fuel cells. Trend widely anticipated in the industrial motor segment, where in recent months, all major players have seen hydrogen versions of their traditionally diesel-powered engines launched. This is to overcome the limitations of electrified propulsion systems. Which are currently unable to provide standard operational timeframes in applications requiring medium-high power levels due to the limited energy storage capacity of batteries. The higher the performance, the higher the energy demands. A reality that makes it impossible to create sports cars capable of offering operational autonomy and mass levels aligned with traditionally powered models.

Heavier vehicles

Hence, and while awaiting an improvement in the performance of chemical accumulators, the need to explore alternatives has led Ferrari to consider the possibility of powering a relatively conventional endothermic engine with hydrogen. Such a unit would enable the creation of a supercar capable of delivering high performance, even during spirited driving on the track, without compromising autonomy. All this while respecting the environment, as the combustion products of hydrogen eliminate nearly all greenhouse gases, carbon dioxide, carbon monoxide, and particulate matter.

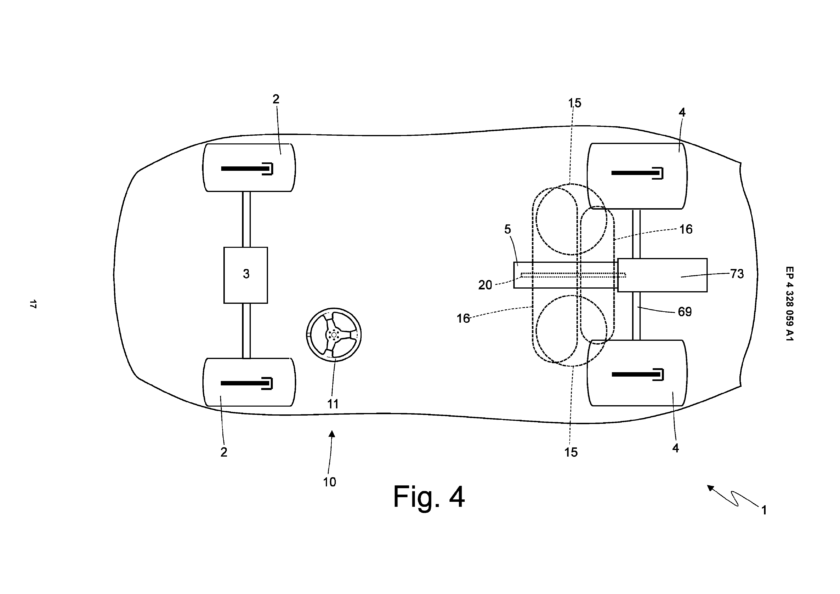

Positioning of the hydrogen tanks. Source: patent US2024/0068397

“The incorporation of such a system into a high-performance car, however, requires an unconventional layout to address the drawbacks of using hydrogen as fuel. Firstly, the low density of the molecule necessitates the use of tanks capable of withstanding pressures up to 700 bar, and possibly even refrigerated. This requires specific shapes, such as spherical or cylindrical, and onboard masses that are more significant than those offered by traditional tanks. This conditioning, which Ferrari itself acknowledges, results in longer and heavier cars compared to those using gasoline-powered engines to achieve the same range.

Six hydrogen cylinders in an inverted configuration

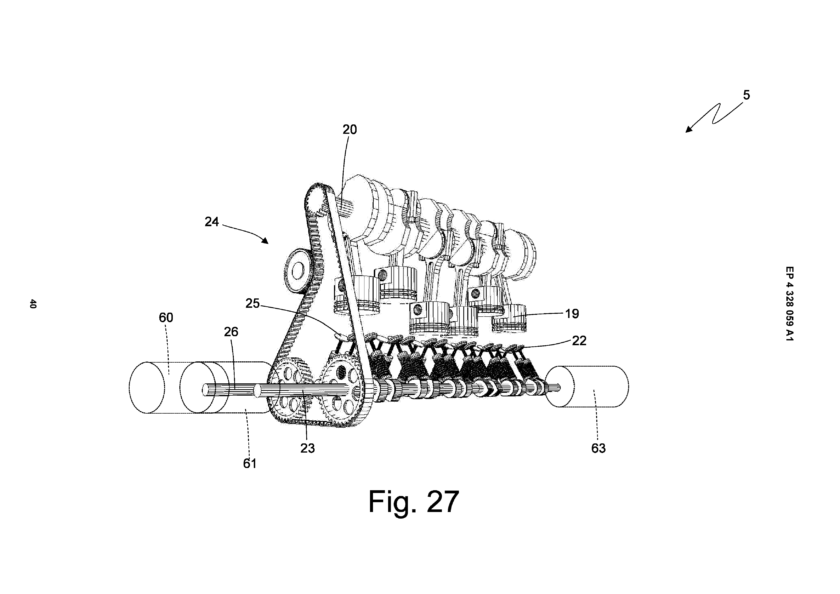

For these reasons, the Ferrari patent proposes a hybrid propulsion system that features a six-cylinder hydrogen engine associated with at least one electric machine operating on the front axle. Leaving the thermal engine to power the rear axle, specifically modulated by a dual-clutch transmission with seven speeds. This solution also accommodates energy recovery objectives during deceleration, but the patent specifies that it is ancillary to propulsion purposes and therefore can be excluded from the system. Regarding the thermal engine, the use of a six-cylinder unit with an inline architecture, but in an inverted configuration, is proposed.

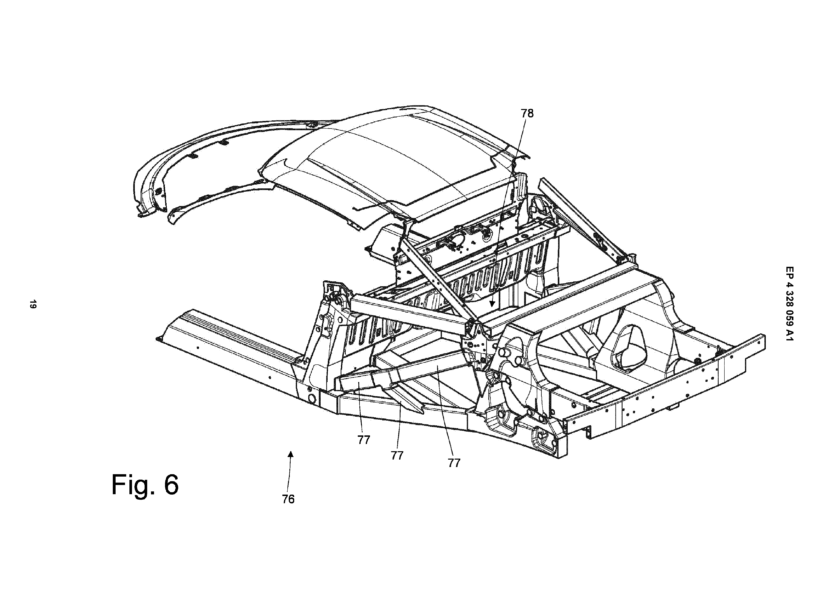

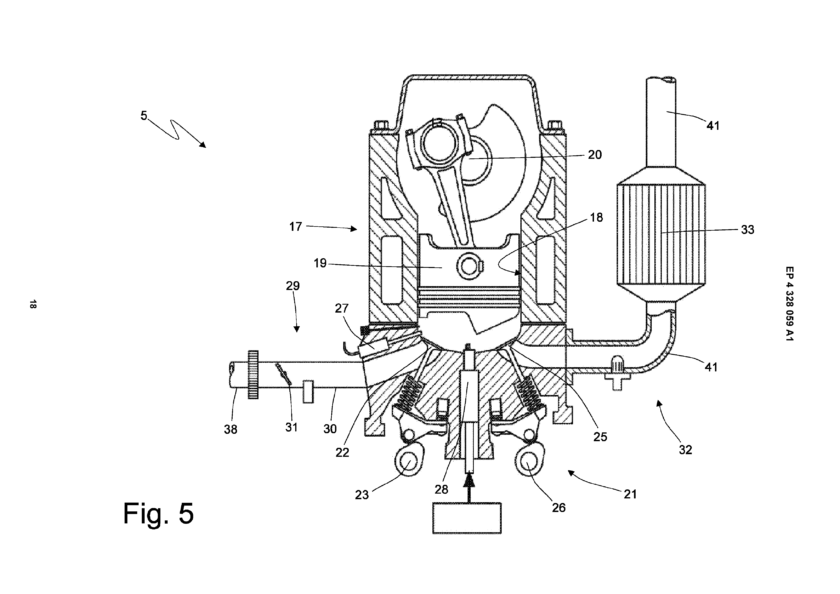

So, with the cylinder head oriented towards the vehicle’s floor and the crankshaft at the top. This solution is specified to be optimal for allowing better accommodation of the hydrogen tanks and does not exclude the use of other engine architectures, such as a ‘V’, or a different number of cylinders. Positioned centrally in the rear of the vehicle, the engine is longitudinally arranged, a choice again driven by the need to make room for the hydrogen tanks. Each cylinder intakes and exhausts through four valves actuated by two camshafts, in turn driven by a belt, a solution that the company admits could be replaced by chain or gear systems. The same applies to the fuel supply, proposed as direct but specifying that it could also be indirect, while the placement of the spark plug in line with the cylinder and the presence of two electrically driven compressors are certain.

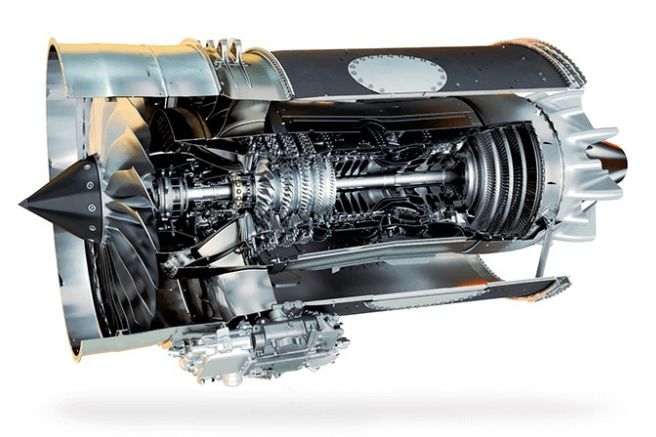

Electrified supercharging

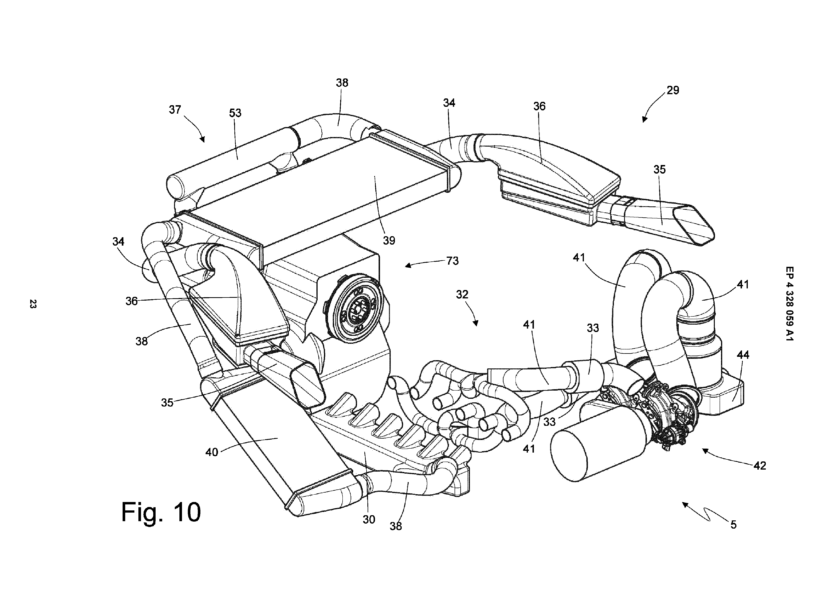

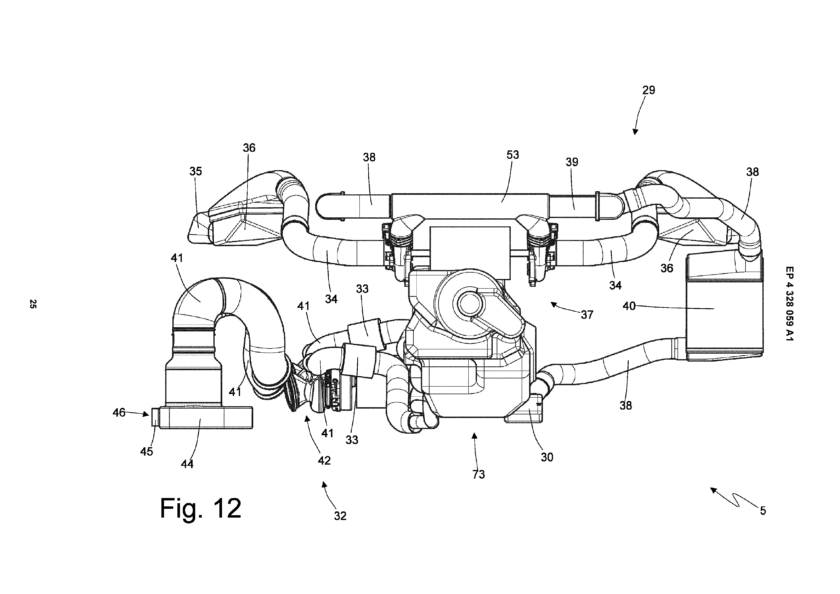

The system involves exhaust gases spinning two turbines connected to two electric generators, with the electrical energy generated being stored in the onboard batteries and subsequently reused to power the compressors. These compressors receive air from two twin ducts positioned on either side of the car, and once they compress the fluid, they send it through two series-connected intercoolers of the air-to-air type to cool it down. In the patent, the first intercooler has a larger volume as it needs to cool down hotter air coming directly from the compressor.

It is worth noting that the generators are mechanically decoupled from each other, while the compressors, positioned above the engine and in front of the first intercooler, are coaxial with each other, connected by a single shaft that makes them integral with the electric motor. The turbines, on the other hand, are positioned under the engine, side by side, with axes of rotation parallel to each other. As mentioned, they drive a specific electric motor through a gear transmission system and each is powered by three cylinders.

Spherical and cylindrical tanks

Although this solution is the most energy-efficient, the patent does not exclude a second possibility inherent in directly driving the compressors by mechanically connecting them to the engine. According to Ferrari, this solution results in a lighter, more compact, and simpler system than the previous one but cannot be electronically controlled. However, regardless of how the supercharging system is designed, the patent hypothesizes the presence of four tanks: two spherical and two smaller cylindrical ones. The two spherical tanks are located on either side of the combustion engine at the base level, while the two cylindrical tanks are arranged transversely and positioned above the thermal engine, one behind the other.

Six-cylinder hydrogen-powered

Aithor: Jacopo Oldani

Translated by ChatGPT