Three thousand square meters divided among areas dedicated to teardown benches (in Italian, the disassembly of engines for potential overhauls) and local and remote diagnostics, along with training areas. All of this is set between past and future, from an exhibition of the most important engines that have shaped the brand’s history over the past hundred years to the latest technologies in electrified systems. This is how the new “Engine Teardown Area,” created by Fpt Industrial within its Turin plant, is presented: a space structured to meet the new assistance and training needs that have emerged in the engine sector. On the one hand, there is a need to develop and produce increasingly complex products. On the other, new propulsion solutions must be conceived, from multi-fuel thermal units to electrified power units. The latter group requires the presence of components that were completely foreign to the engine segment until a few years ago, such as electric power units, high-voltage battery packs, inverters, and dedicated control electronics.

While it’s true that diesel remains the benchmark around which the interests of industry manufacturers revolve, it’s equally true that increasingly complex products have been added to it, necessitating a thorough overhaul of technical support services. This is fundamentally altering the very concept of technical assistance. Whereas until recently, technical assistance was only provided when a problem arose, it now needs to be predictive. This objective requires the organization of diagnostic structures capable of operating remotely, working in tandem with entities dedicated to the continuous improvement of the product. All this starts from the idea that every engine is subject to wear and tear, and therefore, it is essential to offer customers the possibility of having the units overhauled by skilled and trained technicians.

Not coincidentally, the new “Engine Teardown Area” of FPT Industrial also serves as a major training hub, thanks to the presence of a section specifically structured to enable the training of specialized technical personnel. A true academy that allows customers, distributors, students, and internal staff to be trained both theoretically and practically on various propulsion systems for maintenance, management, and problem-solving, based on five training modules. One of these modules is specifically dedicated to fault detection, anomalies, and functional problem resolution.

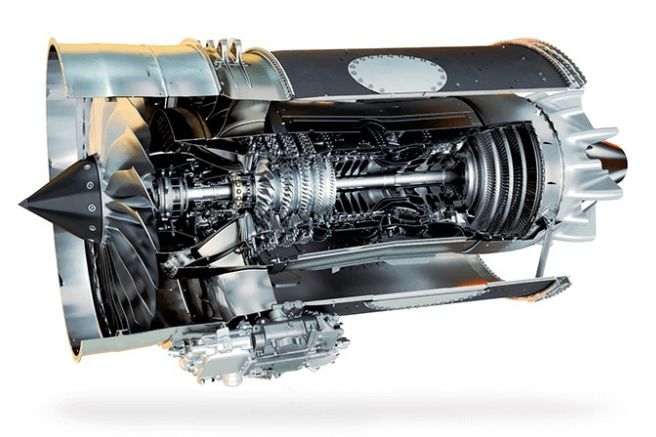

The need to continuously develop the know-how within the area has led FPT to support the sharing of experiences through a digital connectivity system, which, thanks to dedicated cameras at each station, allows all activities to be followed in real-time, even remotely. This solution is designed for customers, distributors, and technicians who need training but cannot travel to Turin, as well as for sharing in real-time the experiences being accumulated in the other four teardown areas of the brand located in the United States, Brazil, India, and Japan. In these spaces, technical activities related to troubleshooting and fault resolution are advanced using benches specifically equipped to accommodate the configurations of each product class, from light engines of two to four liters displacement to the heavy engines of the “Cursor” and “V20” series, passing through the medium engines of the “Nef” series. In this context, there are also specific benches dedicated to the components of the “ePowertrain” of electrified propulsion systems and structures designed to analyze every single component of the engines, from turbocharging systems to piston seals, through compression and timing tests, measurement of compression and valve sealing pressures, not to mention the analysis of fuel and after-treatment systems.

In fact, it happens that an engine can be monitored in all its parts to identify worn components or detect anomalies that could lead to actual breakdowns. “Nobody is perfect,” goes a popular saying, and not even the most meticulous analysis can prevent a fault from occurring. In such cases, further activities come into play, specifically aimed at fault analysis, so that the technical offices in charge can evaluate if and how to introduce specific improvements on future engines or advise customers to modify the engine’s interface with the machine as needed.

In this regard, the analysis of the fault codes reported by the engine control unit in relation to the damage and the analysis of the usage history are fundamental. This data, taken together, helps determine whether the unit has always operated as designed or has been subjected to abnormal uses, such as overloading, excessively high speeds, use of poor-quality lubricants or fuels, or deterioration due to overheating. It also considers the possibility that scheduled maintenance has been neglected or that the engine has been subject to interventions not compliant with the manual procedures. This analysis also allows for updating or adding new procedures if necessary to ensure greater reliability of the units.

With an eye toward reducing waste and optimizing component life, FPT has not overlooked the possibility of regenerating mechanical parts, advancing the disassembly of units, and subsequently reassembling them once the individual components have been regenerated at the brand’s dedicated divisions.

Real-time control

The digital connections of the new teardown area are aligned with the customer service strategies that FPT Industrial has developed to improve the productive efficiency of the machines on which its engines are installed. Fundamental in this regard is the real-time monitoring service, which, thanks to the remote connection of individual units through the dedicated Control Room, enables proactive assistance services by signaling the need for maintenance or repair before machine downtime is induced by mechanical failures. This is also possible thanks to the ability to perform advanced diagnostics remotely once all information on the units’ operational status is shared via the dedicated “MyFPT” mobile app, interfaced with the unit via a specific connection “dongle” inserted into the engine’s diagnostic port. This system also allows the company to interface directly with the engine’s electronic management system, intervening remotely on the software to clear alarms once the required maintenance or repair interventions have been carried out or to eliminate any errors that result in malfunction warnings. This approach, once again, maximizes engine operability by reducing intervention times.

Title: Fpt Industrial, new teardown dimension

Translation with ChatGPT