Europe bans endothermic engines and loses over a century of engineering know-how to prioritize alleged environmental sustainability, which the European automotive industry is not equipped to tackle on equal terms against China, which is grateful to Europe by becoming the world’s leading exporter.

The European Union recently initiated an anti-dumping investigation against Chinese vehicle manufacturers. They are accused of reducing production costs through low-cost labor, unfair trade practices, and government subsidies that undermine fair competition. The extensive use of state subsidies by Chinese companies, however, has been known for years. As the Dragon’s government has invested around €57 billion in support of electric mobility between 2016 and 2022. Compared to about €12 billion allocated by the United States during the same period.

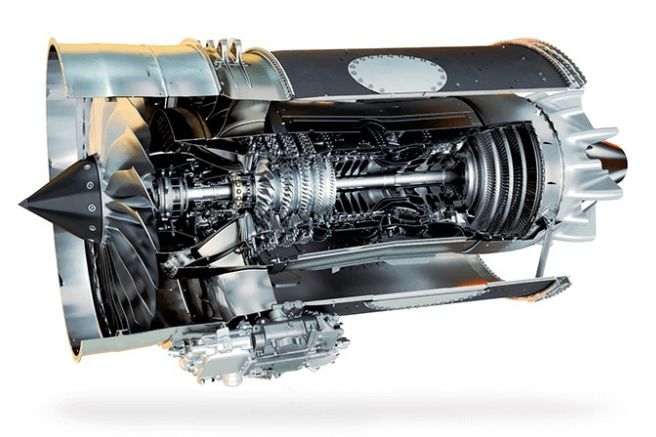

This vast difference alone demonstrates how Brussels’ reaction is almost too late, both in terms of timing and form. In terms of timing, because China has been decisively pursuing an industrial policy aimed at leveraging the energy transition paradigm to establish itself as the leading global player in green and digital technologies for about 20 years, with significant financial resources. In terms of form, the real negative impact is the decision to ban endothermic engines in the Old Continent by 2035. This move disregards over a hundred years of technological know-how, which still represents the flagship of European automotive engineering.

Global production in the hands of China

The latest electric vehicles are anything but a showcase of advanced mechanics. Electronics dominate instead. Moreover, they are largely borrowed from consumer electronics, which the Celestial Empire now handles as competently as the United States. The same applies to batteries, an area in which China controls both 60 percent of global production and the raw materials needed for their manufacture. Last year, it extracted nearly three-fifths of the rare earth elements used as components in electronics, refining 60 percent of the world’s lithium and 80 percent of cobalt. Two essential minerals for modern high-efficiency batteries.

The mechanical aspect of electric vehicles, on the other hand, is stripped down to the essentials. It lacks the endothermic engines and transmissions that have always been a unresolved mystery for the Chinese automotive industry due to the hundreds of moving components, the use of increasingly refined materials, and the need for in-depth research on gas and fluid-dynamics. All these are unnecessary skills for developing full electric powertrains, which rely on simple electric motors operating together with single-speed transmissions. They do not require drive shafts, clutches, dedicated lubrication and cooling systems. Or aesthetic-functional solutions that impact the vehicle’s design, such as air intakes for the radiator.

The halt to engines will cost 8% of the European GDP

It’s natural, then, that the mechanical simplification of vehicles has allowed entities with fewer skills and know-how to gain ground in a market where they previously held a marginal position. They can also benefit from lower production costs and shorter development times compared to Western standards. Which have effectively raised the stakes not only economically but also socially. According to data from ACEA, the association of European manufacturers, there are approximately 13 million continental workers directly or indirectly employed in the automotive industry. Accounting for about seven percent of the entire workforce in the Old Continent.

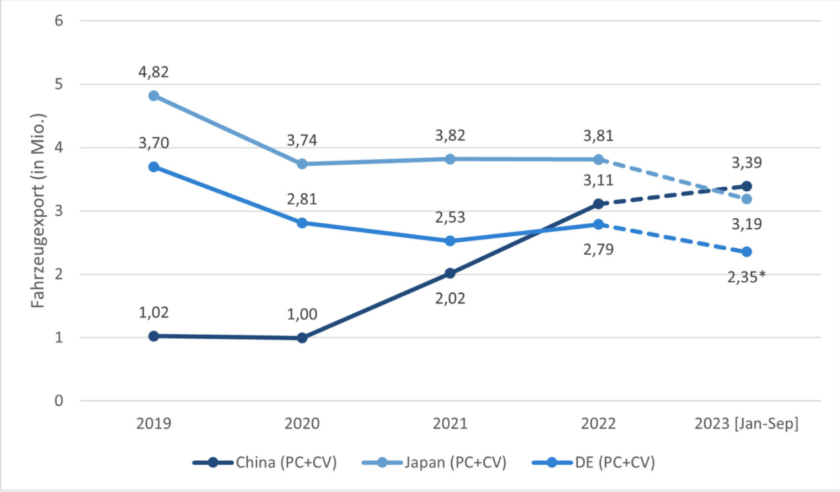

The sector also provides annual tax revenues to the member states hosting facilities, amounting to approximately €375 billion, and its turnover overall represents over eight percent of the entire European Union’s GDP. These numbers are expected to contract significantly with the banning of endothermic engines and the inability to compete on equal terms in private electric mobility with China, which last year became the world’s leading exporter of cars, surpassing Japan.

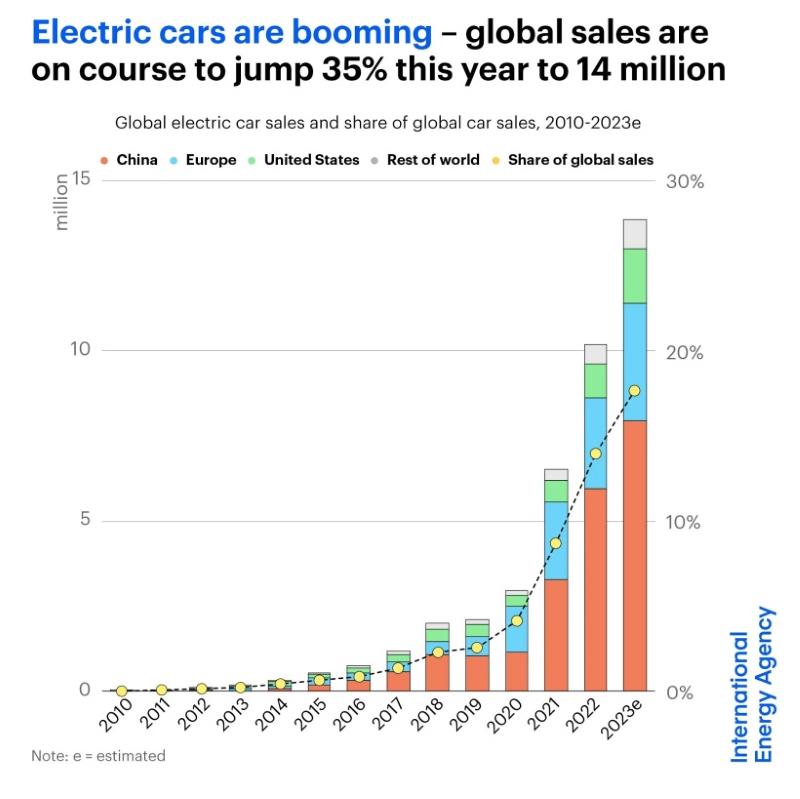

Chinese attempts to expand into foreign markets were disappointing until a few years ago, with volumes of fewer than 500,000 units until 2020. However, from then on, China changed gear, reaching over four million vehicles in 2023. While Chinese exports were initially directed almost exclusively to less developed countries, today almost half of the cars shipped abroad arrive in Europe, two-thirds of which are electric.

Average price: €31,829

The growth of the domestic Chinese market, continually supported by government subsidies, has served as a catalyst for companies capable of autonomously covering many key aspects of the supply chain. BYD Group, recently in the headlines for surpassing Tesla in electric car sales data for the fourth quarter of 2023 globally, actually began its operations in the 1990s as a battery manufacturer before transitioning to electric and plug-in hybrid vehicles only from 2008 onward.

This progressive and planned growth, according to an analysis by the Swiss bank UBS, allows BYD to minimize production costs by 25 percent compared to European and American manufacturers. It is also thanks to this that, according to research by JATO Dynamics, Chinese electric cars cost about 30 percent less than their European and American counterparts. With an average price last year of €31,829, compared to €55,821 and €63,864 respectively in Europe and the United States.

In light of this, Beijing’s ascent in the automotive industry appears to be a true success story. Politically guided and warmly supported by manufacturers behind generous state subsidies. Meanwhile, the European industry seems to be moving in the opposite direction. The electric vehicle market is indeed inaccessible to many consumers in terms of costs. Bureaucracy is constrained by restrictions on state aid, and the absence of a strategic vision at the political level has underestimated the need to create stable and secure supply chains, shielded from potential foreign retaliations, instead favoring outsourcing and low-cost imports.

Europe loses know-how and China is grateful

A situation destined to escalate further with the imminent saturation of the Chinese market. Which in practice will increasingly push Chinese automakers to intensify their commercial offensive towards the West. According to the consulting firm AlixPartners, annual sales of Chinese full electric vehicles in foreign markets will reach nine million by 2030. These volumes would translate into a 30 percent global market share and a 15 percent European market share for Chinese brands. This trend is also confirmed by Transport & Environment, the NGO that has heavily advocated for the ill-advised European ban on endothermic engines scheduled for 2035. They estimate that Chinese electric vehicles could reach a global market share of 18 percent by the end of next year.

If Akio Toyoda’s hypothesis, the chairman of the board of Toyota, holds true, stating that electric cars will cover 30 percent of the global market, it implies that almost two-thirds of that 30 percent will be in the hands of Chinese manufacturers. Meanwhile, they will have also developed or acquired the necessary skills to produce vehicles powered by endothermic engines. The risk is that without decisions made by 2030, the European automotive industry could collapse, and worse still, the environment may not benefit from it. This is because environmental protection seems to be an aspect of production that the Chinese are currently not interested in.

Europe loses know-how and China is grateful

Author: Andrea Castelli

Translated by ChatGPT