In the aerospace sector, the decarbonization of propulsion systems is increasingly turning toward hydrogen as a viable alternative fuel for thermal engines. While this approach presents several engineering challenges, it offers the potential to match the performance and range of conventional fossil fuel-powered engines

In recent years, the aviation industry has significantly accelerated the development of hydrogen-based propulsion technologies, aiming to replace fossil-derived fuels in thermal engines. Although hydrogen is often associated with electrified propulsion through fuel cells, its use as a direct combustion fuel offers a major advantage: the ability to retain much of the existing turbine propulsion system architecture. While fuel cells may be more suitable for small to mid-size aircraft, liquid hydrogen combustion is emerging as the most promising solution for larger commercial planes, enabling longer flights with drastically reduced emissions.

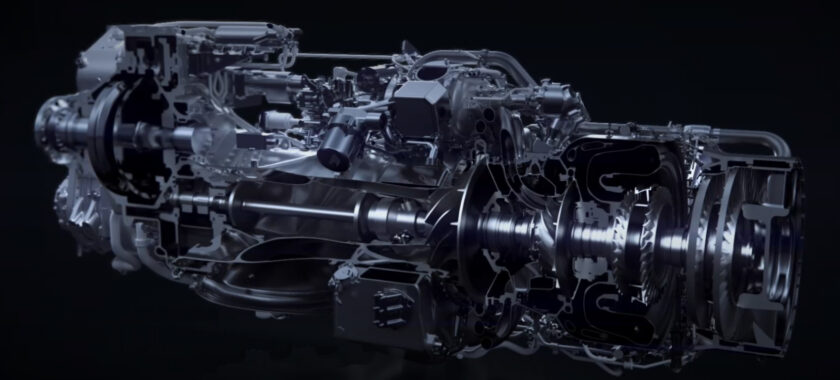

Major aerospace players—including Rolls-Royce, Pratt & Whitney, Safran, and Airbus—are investing in hydrogen engine technologies with the goal of achieving zero-emission aviation by 2050. One standout innovation is Pratt & Whitney’s “HySIITE” (Hydrogen Steam Injected, Inter-cooled Turbine Engine) architecture. This system promises up to 35% improvement in energy efficiency and a 99% reduction in nitrogen oxide emissions. It leverages the cryogenic properties of liquid hydrogen and recycles water vapor to boost thermodynamic performance. This is integrating components such as evaporators, condensers, and water separators that utilize exhaust heat to generate steam for reinjection into the engine cycle.

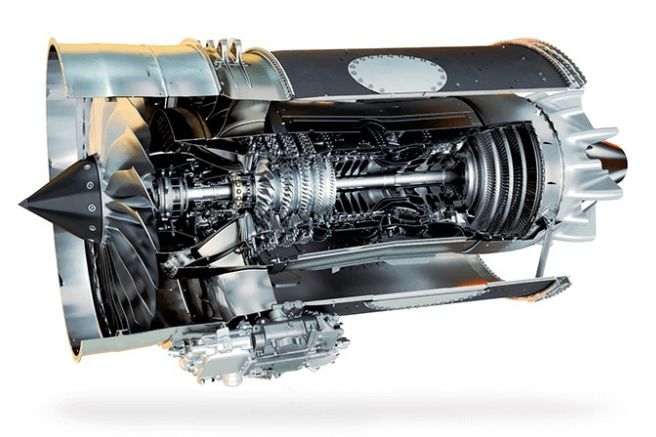

Pratt & Whitney is also testing hydrogen combustion on a modified “PW127XT” turboprop engine under the “HyADES” (Hydrogen Advanced Design Engine Study) program, funded by the Canadian government. Initial trials involve gaseous hydrogen, with plans to transition to liquid hydrogen testing. The company is also advancing its “Turbine Engine Advanced Materials for Efficiency” initiative, which focuses on next-gen materials to enhance thermal efficiency.

Airbus, for its part, is exploring multiple hydrogen propulsion configurations with the aim of bringing the first hydrogen-powered commercial aircraft to market by 2035. A major milestone will be the 2026 test of a modified General Electric “Passport” turbofan engine on an A380 aircraft, conducted in partnership with CFM International—a joint venture between GE Aerospace and Safran Aircraft Engines.

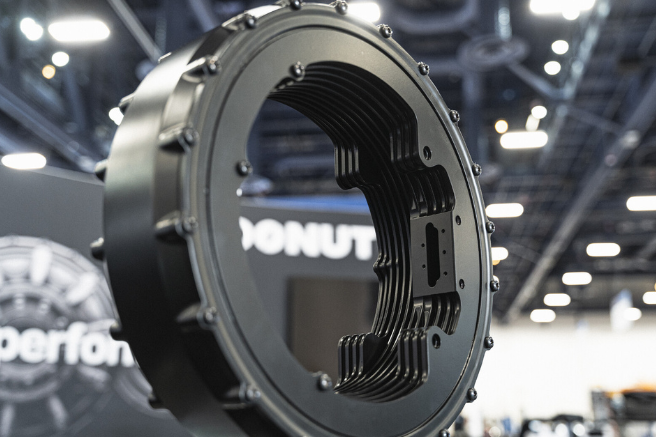

Safran is also making strides in hydrogen technology, having completed the first successful ground test of a gaseous hydrogen-powered “TP-R90” engine as part of its “BeautHyFuel” project. Though gaseous hydrogen is easier to handle, it still presents significant storage challenges, requiring high-pressure tanks. In contrast, liquid hydrogen, despite its complex cryogenic storage needs, offers greater energy density and is better suited to aviation applications.

Rolls-Royce has redirected its focus toward hydrogen combustion for business jets and commercial airliners, following the discontinuation of several electric propulsion projects. After successfully testing a Pearl 700 turbofan running on gaseous hydrogen, Rolls-Royce is now building a testbed at NASA’s Stennis Space Center in Mississippi for trials of a modified Pearl 15 engine. It has also tested a green hydrogen-powered AE 2100A turboprop engine. Alongside EasyJet, Rolls-Royce is a founding member of the Hydrogen in Aviation Alliance, which is working to develop hydrogen propulsion systems for narrow-body aircraft like the Airbus A320.

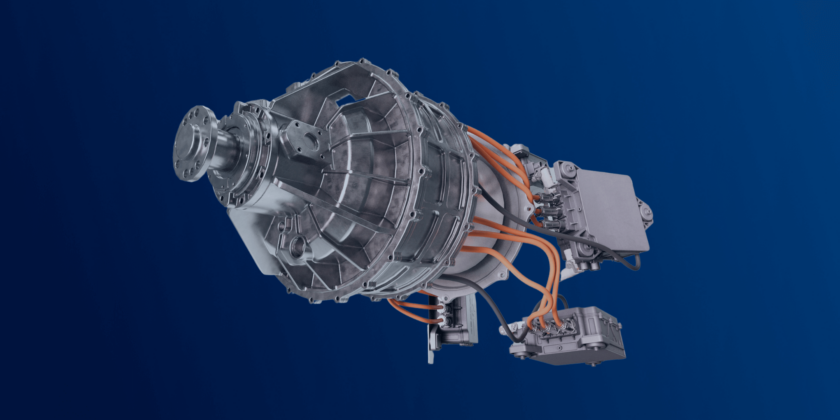

Gkn Aerospace is actively involved in cryogenic hydrogen storage solutions and leads the “H2Flyght” project, which aims to deliver a 2-megawatt hydrogen-electric propulsion system for regional aircraft.

When it comes to fuel cell-powered aircraft and eVTOLs, companies like Joby Aviation and ZeroAvia are setting new benchmarks. Joby has tested a prototype capable of achieving a range of up to 850 kilometers—over five times the range of its battery-powered equivalent. ZeroAvia is developing the “ZA600,” a 600-kilowatt all-electric hydrogen powertrain for regional aircraft, with certification expected by 2025. The company is also working on a 2-megawatt version for 80–90 seat aircraft.

Despite its promise, hydrogen aviation faces several technical hurdles. Chief among them is storage, which requires either cryogenic or high-pressure tanks, adding complexity to airport refueling infrastructure. Hydrogen has a lower volumetric energy density than traditional jet fuels, necessitating larger or pressurized tanks to achieve comparable flight ranges. To maintain its liquid state, hydrogen must be stored at cryogenic temperatures of -253°C, posing significant challenges for tank design and thermal insulation.

Safety is another major concern due to hydrogen’s high flammability, demanding stringent safety standards and protocols across all handling stages—including transfer and fueling operations. Hydrogen’s tendency to diffuse rapidly means leak prevention systems are essential, and its combustion generates water vapor, potentially increasing contrail formation with climatic impacts. For this reason, systems are being studied to recover and mitigate excess vapor emissions.

Overall, the aviation sector is making substantial progress toward adopting hydrogen as a sustainable fuel, leveraging a hybrid approach of fuel cells and direct combustion. While the transition to hydrogen will require major investment in infrastructure and R&D, it remains one of the most promising strategies to decarbonize air travel and meet net-zero targets by 2050.

Title: Engines, Engine, hydrogen takes flight

Translation with ChatGPT