Porsche has introduced an innovative patent for a six-stroke engine designed to enhance the energy efficiency of its propulsion systems while addressing the challenges of decarbonization.

The European Union’s green policies are accelerating deindustrialization across the continent, triggering economic stagnation and recession. Germany, heavily impacted, is now officially in a technical recession, with the automotive sector among the hardest hit. Last year, vehicle registrations dropped significantly, with August recording double-digit declines: Germany -28%, France -24%, Italy -13.5%, and Spain -6.5%. Even electric vehicle sales fell by over 40%, despite substantial investments from automakers.

Additionally, strict CO2 reduction targets below 95 g/km risk worsening the Eurozone’s economic outlook.

Porsche’s Six-Stroke Engine: A Revolutionary Innovation

Amid this crisis, one might expect policymakers to reconsider their strategies, especially following recent election results that reflected less support for green parties. Meanwhile, European carmakers are investing in innovative technical solutions to safeguard internal combustion engines (ICEs), which remain crucial for both the European and global economies, while working toward the EU’s 2050 decarbonization targets.

Standing out among these solutions is Porsche‘s patent for a six-stroke engine, developed in collaboration with the Technical University of Cluj-Napoca in Romania, where Porsche has operated a research and development center since 2016.

This invention aims to combine the advantages of two-stroke engines (higher specific power) with those of four-stroke engines (lower emissions and greater reliability). The result is an engine capable of performing two combustions per cycle, enhancing energy efficiency compared to traditional four-stroke engines.

Patent Details

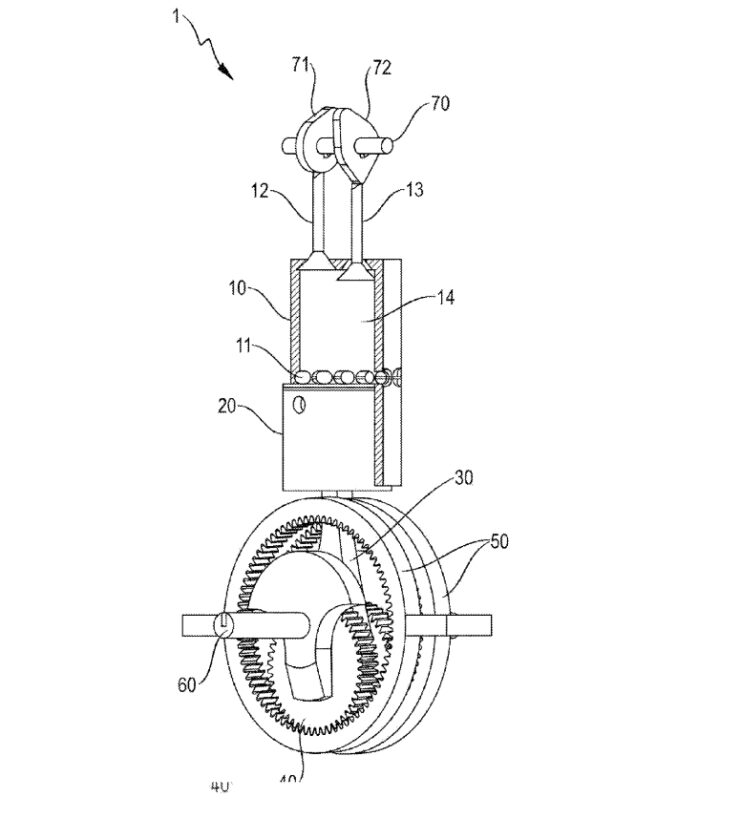

The patent (US 2024/0301817 A1), iled with the United States Patent and Trademark Office, outlines a system that leverages gear mechanisms to optimize piston movements, ensuring improved thermodynamic performance. Key technical features include:

- Gear teeth that regulate piston oscillations.

- A cylinder washing system using radially positioned exhaust ports.

- Two separate combustions per cycle to maximize energy extraction.

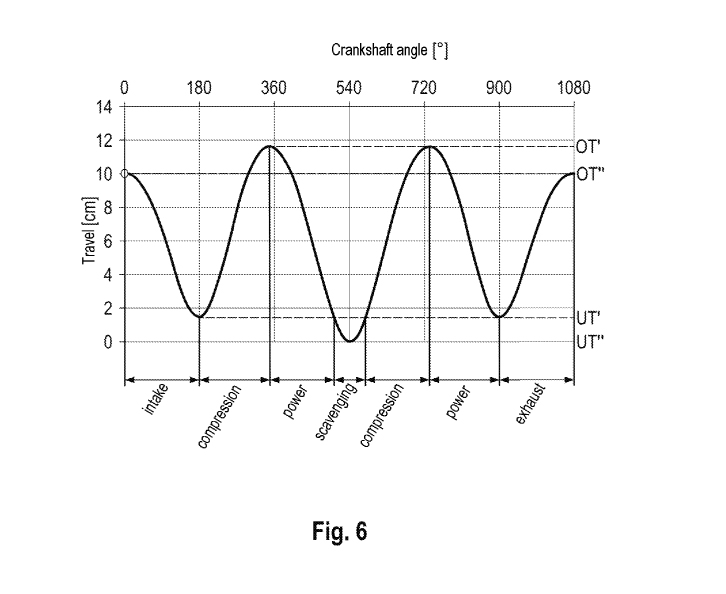

The engine completes a full work cycle every 1,080 degrees of crankshaft rotation (three rotations), encompassing six strokes: intake, compression, expansion, second compression, second expansion, and exhaust.

How the Six-Stroke Engine Works

The engine operates with two alternating sequences, each consisting of three strokes. This configuration combines the benefits of two-stroke engines, where power generation occurs with every crankshaft revolution, resulting in higher specific power, with the advantages of four-stroke engines—lower emissions, greater reliability, and enhanced unit longevity.

The increased efficiency is achieved because, unlike a four-stroke engine, where combustion occurs only during the expansion phase, transforming chemical energy into mechanical energy during one of the four strokes of the thermodynamic cycle, the six-stroke engine enables combustion to occur twice within a complete cycle. This cycle involves six piston strokes, significantly improving efficiency and power output.

The engine features an active phase every three piston strokes, introducing significant modifications compared to traditional engines.

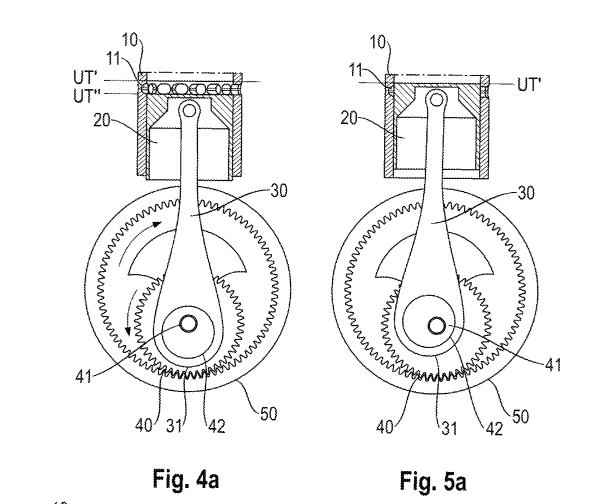

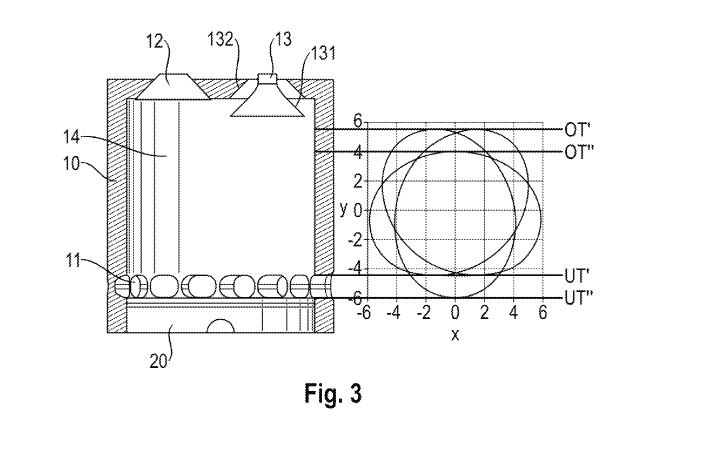

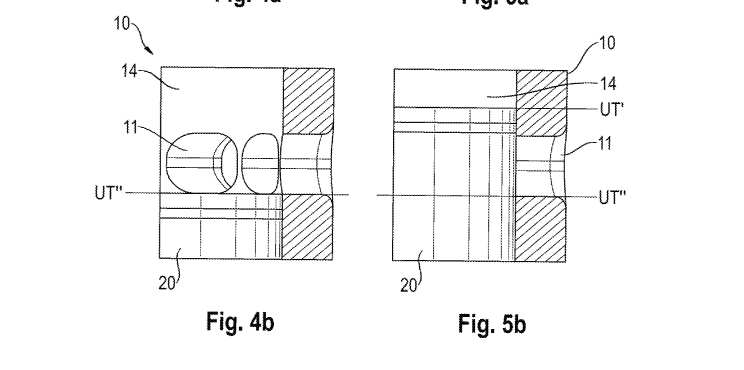

Firstly, an interface between the connecting rod’s big end and the crankshaft pin utilizes a gear mechanism that rotates within a circular toothed crown. This setup is similar to an epicyclic gear system, but with only the crown and a single rotating satellite inside it. Additionally, the geometry of the connecting rod’s pin is offset from the crankshaft axis, enabling precise adjustments in the amplitude of the piston’s oscillations during its strokes.

This mechanism causes the connecting rod’s big end to trace hypotrochoidal geometries, defining two distinct top and bottom dead centers across the six piston strokes. In this configuration, the engine completes a full work cycle every 1,080 degrees of the crankshaft rotation—equivalent to three full revolutions—comprising six distinct strokes: intake, compression, expansion, followed by a new compression phase, a second expansion, and finally, the exhaust phase.

Double Dead Centers

Specifically, the engine cycle involves an initial intake phase from the lower top dead center to the upper bottom dead center. A second compression phase then moves the piston to the upper top dead center, followed by combustion and expansion until it reaches the lower bottom dead center. Upon reaching this position, exhaust ports positioned radially at the base of the cylinder open, allowing the cylinder to be flushed with the expulsion of burnt gases and the injection of a fresh charge through dedicated intake ports or additional intake openings.

In this system, a new compression phase is possible without opening the main exhaust valves, enabling a new combustion followed by expansion from the top dead center (TDC) to the bottom dead center (BDC). The cycle then completes the piston’s final stroke, where the exhaust gases are expelled through the valves, reaching the bottom dead center (BDC).

The patent specifies that the scavenging ports can be sized according to the amount of gases to be expelled or could be divided into smaller ports to optimize gas expulsion. However, it remains unclear how the second charge of the mixture is injected, leaving room for various potential solutions for practical implementation. This patent is certainly an interesting engineering exercise, but its production and commercialization will face significant challenges.

Challenges and Future Prospects of the Six-Stroke Engine

Despite the ingenuity behind the design, this technology presents several challenges:

- Mechanical complexity, both in the crankshaft mechanism and in the intake and exhaust systems.

- Increased component count, which leads to higher weight, size, and production costs.

- Difficulty in combustion control, requiring an advanced system to manage the various operational phases.

These challenges make mass production difficult. However, the six-stroke engine represents a significant engineering achievement that could inspire further developments in the automotive industry.

Final Considerations

Internal combustion engines remain essential for the European economy, particularly in the absence of competitive alternatives and adequate infrastructure. Innovations such as Porsche’s six-stroke engine show that engineering can provide real solutions to sustainability challenges, while also preserving Europe’s technological legacy.

Title: Porsche’s Six-Stroke Engine: A Game-Changing Innovation for Decarbonization

Author: Jacopo Oldani