FPT Industrial has reaffirmed its position as a key player at the Dakar 2025, the 47th edition of the world’s toughest rally raid, claiming nine of the top ten positions in the final standings thanks to a CURSOR 13 engine designed to deliver one thousand horsepower and ensure outstanding performance in extreme conditions.

At Dakar 2025, Iveco vehicles powered by FPT Industrial’s Cursor 13 engine swept the podium and secured nine of the top ten spots in the Truck category. As the Exclusive Technical Partner, FPT Industrial supported the de Rooy FPT teams, led by top drivers Aleš Loprais, Vaidotas Žala, and Anja Van Loon. Loprais, leader of the InstaTrade Loprais Team de Rooy FPT, achieved third place with the iconic Iveco Powerstar 2024/2025. Powered by the Cursor 13 engine specifically designed to deliver superior performance and reliability in extreme conditions.

Exceptional Performances in the Saudi Desert

New driver Vaidotas Žala of the Skuba Team de Rooy FPT and Anja Van Loon of the Fried Van de Laar Racing Team de Rooy FPT also tackled the challenges of the Dakar with remarkable success, finishing fifth and eighth respectively. Both drivers delivered their best-ever performances, with Žala achieving six stage podiums and Van Loon securing a prestigious fourth-place stage finish.

An Epic Journey Across Dunes and Special Stages

This edition, considered one of the most challenging ever, featured 12 stages over 8,000 kilometers between Bisha and Shubaytah, with more than 5,000 kilometers of special stages. Loprais stood out with eight top-three finishes and five stage victories, demonstrating the effectiveness of engines engineered for extreme conditions.

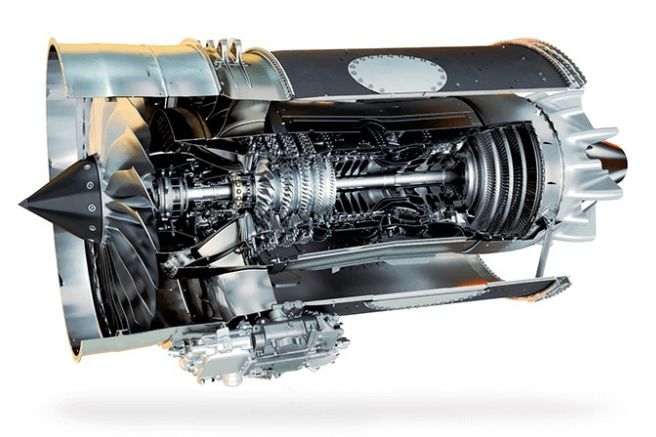

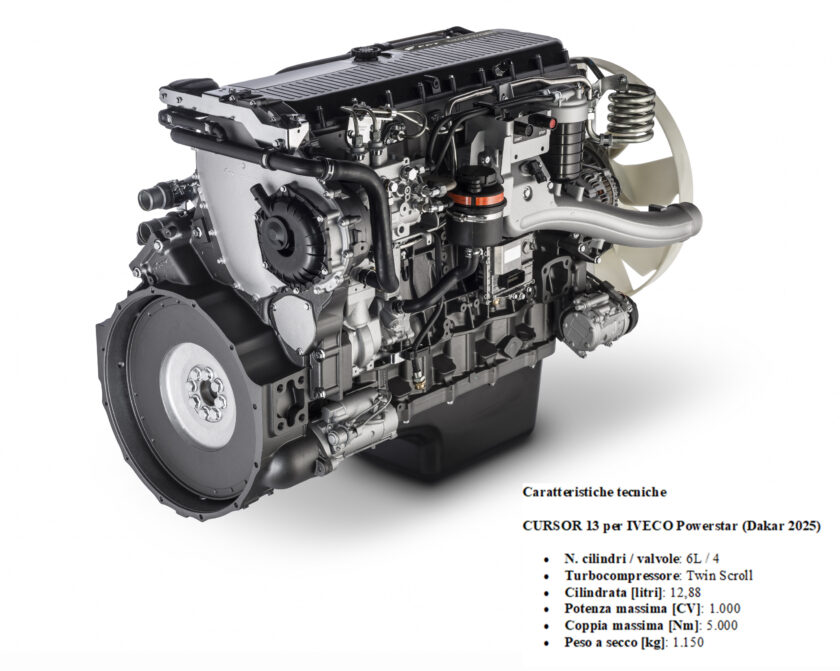

The Technology Behind the CURSOR 13 Engine

The Cursor 13, the beating heart of the winning vehicles, was designed to deliver maximum power and durability. It reaches 1,000 horsepower even under the harshest conditions. Beyond the Dakar, these engines are ideal for heavy-duty trucks exceeding 16 tons gross vehicle weight. It offers best-in-class performance and transient response with low fuel consumption.

FPT Industrial’s patented HI-eSCR technology, a no-EGR solution, ensures a low Total Cost of Ownership (TCO), with a DPF featuring passive regeneration up to 600,000 kilometers and extended oil change intervals of up to 150,000 kilometers. Reduced oil consumption further enhances operational availability and cost savings.

Title: One Thousand Horsepower in Extreme Conditions

Source: Fpt Industrial